Glossary

- TDS: (Tap drill size)

- The size of the hole that must be drilled before a tapping operation.

- Imperial UN: (Imperial Unified National thread form)

- A standard that describes the shape of an internal or external thread using imperial inch dimensions. Making a thread that follow these specifications will ensure that it will work with threaded holes or shafts made by other manufacturers that follow these

common specs.

- Metric UN: (American Metric Unified National thread form)

- A standard that describes the shape of an internal or external thread using

metric millimetre dimensions. Making a thread that follow these specifications will ensure that it will work with threaded holes or shafts made by other manufacturers that follow these

common specs.

- NOTE: The American Metric UN thread standard is compatible with the international ISO

thread standard.

- Outside diameter:

- This is the biggest diameter of the helical portion of a thread. The biggest external diameter of a Screw or the biggest internal diameter of a threaded hole.

- NOTE: The size of the hexagon of a bolt or nut has no relevance when defining a thread size.

- TPI: (Threads per inch)

- The number of thread, or "V"s along a one inch length which in turns, defines the size of the "V" shape of the helical portion of a thread.

- NOTE: If the length of the threaded portion of a screw or threaded hole is shorter or longer than one inch, the size of the "V" shape is still defined by the number of thread that would fit along a one inch length.

- Pitch: (Distance between each thread, or "V"s.)

- The distance the a screw or nut will advance every 360° turn.

- NOTE: Most basic sizes have a coarse and a fine series of thread.

- Cutting Tap:

- A tool that makes the helical portion of a threaded hole by cutting material as it moves along a predrilled hole. Cutting taps usually have sharp "flutes", somewhat like the spirals of a drill, where the chips can accumulate and be ejected out of the hole

- NOTE: Cutting taps come in sets of 3; A starter tap, a midway tap, and the bottoming tap. They should be used in that order when tapping holes that do not break through.

- Form tap: (Cold forming tap)

- A tool that makes the helical portion of a threaded hole by forming, or deforming, the material as it moves along a predrilled hole. These taps have no "flutes" and are usually oval shaped or not quite round.

- NOTE: The tap drill size of a hole that will be cold form tapped is usually bigger than it cutting tap counterpart.

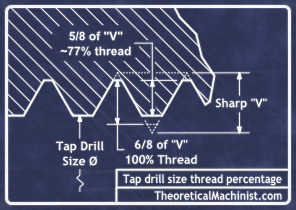

- Thread percentage: (77% thread is what you want to use)

- A 100% thread is 3/4qtr, or (6/8th), of the full 60° triangle which is the maximum allowed height of a full thread, the "V" shape, including flats. The UN specification specifies that the common height of a thread should be 5/8th of this maximum height.

75% to 80% thread roughly equals 5/8th of this maximum height.

- NOTE: If tapping idfficult to machine materials or using small taps, use a lower thread percentage such as 60% to 70%.

Updated: 19 December 2019